Welcome to Blue Book!

Are you ready to join the thousands of companies who rely on Blue Book to drive smarter decisions? View our plans and get started today!

Still have questions? We’d love to show you what Blue Book can do for you. Drop us a line– we’ve been waiting for you.

Invisible issues

Earl’s Organic Produce, a wholesale distributor in San Francisco, has launched a companywide campaign to produce zero waste by 2020. Katherine Vining, the company’s sustainability and vendor compliance manager, says that while much of the waste is evident, there are other parts of the ‘waste chain’—in growing, shipping, packaging, and distribution—consumers never see.

Examples include fruit that falls off trees and is unmarketable, or the plastic used to wrap pallets of produce, which often isn’t recycled. Between getting from the farm to the distributor to the customer, plastic has a life of several hours to several days before it goes in the trash.

Waxed boxes are another issue: covered with paraffin wax (a petroleum byproduct), these boxes have to be durable enough to withstand the moisture and temperature of hydrocoolers. But because of the paraffin coating, they cannot be recycled.

“We divert as much waste from the landfill as possible, but the whole lifecycle is bigger than what we see,” comments Vining, “and all along the supply chain: the distributor, the retailer, the consumer—everyone wastes. No one sector is more responsible.”

Meghan Stasz, part of the Food Waste Reduction Alliance, has come to the same conclusion. Jointly funded and staffed by the Grocery Manufacturers Association, the National Restaurant Association, and the Food Marketing Institute, the Alliance and its partners up and down the supply chain aim to reduce food waste, increase food donations, and find and promote alternatives to tossing food in landfills.

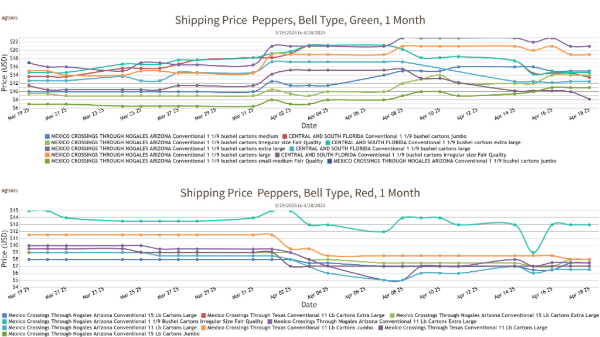

In addition, transportation issues can be responsible for fuel waste and pollution. Produce, in particular, is often taken to a central distribution point (a warehouse or major center) before being transferred for delivery to retailers, restaurants, and, ultimately consumers. Loads consolidated for delivery may travel back and forth across town or several states before reaching a final destination, and of course, this affects shelf life. “Inefficient warehouse locations, huge distances between distribution centers, and backtracking can all be factors that contribute to waste,” asserts Fairchild.

High-tech solutions

With statistics of food waste making headlines, growers, retail chains, and industry groups are implementing a variety of solutions from large-scale compost operations to anaerobic digestion to tackle the ongoing problem.

The Kroger Company is among those leading the way, teaming up with the EPA in 2010 for energy efficiency and installing a system that converts food waste into energy in 2013 to help power its 650,000-square-foot distribution center in Compton, CA. Using the naturally occurring process of anaerobic digestion, the system converts food waste, manure, and sewage into renewable biogas to power the center’s operations. Kroger’s anaerobic conversion system aims to process more than 55,000 tons of organic waste per year. For its ongoing efforts, the company was named the EPA’s Energy Star Partner of the Year for 2015.

Efforts to reduce waste at Stemilt Growers in Wenatchee, WA have resulted in a multipronged approach. According to director of marketing Roger Pepperl, the company has invested heavily in state-of-the-art cooling processes, including mobile hydrocoolers for cherry orchards. “The fruit is usually cooled within an hour of harvest to take the field heat out of the pit,” he explains. “Our process also includes jet coolers, which can bring the temperature of the cherries in a packed box down to the 33-34 degree range within an hour.”